Utilizing hybrid configurations can significantly enhance performance and fuel efficiency in racing vehicles. The integration of electric motors with traditional power sources allows for rapid acceleration and improved throttle response, thus providing a competitive edge on the track.

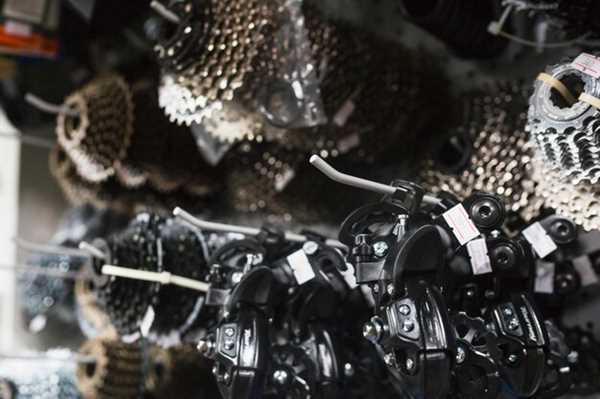

Carbon fiber components are increasingly being adopted in the construction of power units. These materials offer substantial weight savings compared to conventional metals, which translates to improved handling and stability during high-speed maneuvers. Engineers are encouraged to explore advanced composites to maximize the benefits of reduced mass without compromising strength.

The implementation of additive manufacturing techniques has transformed the production process of internal components. This approach enables the creation of complex geometries that are often impossible to achieve with traditional methods, resulting in improved airflow and thermal management. Teams should invest in 3D printing capabilities to allow for rapid prototyping and on-the-fly adjustments during the racing season.

Finally, data analytics plays an essential role in optimizing engine performance. Real-time telemetry can provide insights into various parameters, enabling teams to make informed decisions regarding tuning and setup. Utilizing advanced algorithms to analyze this data allows for the identification of patterns that can be leveraged for competitive advantage on race day.

Impact of Hybrid Technology on Performance and Efficiency

Hybrid systems significantly boost racing performance through enhanced torque delivery and reduced fuel consumption. By integrating electric motors with conventional power units, teams can optimize acceleration and cornering speeds. This combination allows for quicker lap times while maintaining energy efficiency, a key factor in endurance competitions.

The use of regenerative braking captures energy that would typically be lost, providing a boost for optimal power management. This results in improved weight distribution and balance, enhancing vehicle handling during high-speed maneuvers. Data shows that cars utilizing hybrid systems can achieve 20-30% better fuel economy compared to their purely combustion counterparts.

Incorporating hybrid power sources not only meets regulations but also offers strategic advantages in race scenarios. Teams can deploy electric power for overtaking or managing tire wear without sacrificing overall power output. Continuous advancements in battery technology further extend the potential range and efficiency of these systems, ensuring competitiveness across various track conditions.

Ultimately, the integration of these advanced systems necessitates a shift in design philosophy, focusing equally on power and sustainability. As hybridization continues to evolve, its impact on racing dynamics will remain profound, shaping future performance paradigms.

Integration of AI and Data Analytics in Engine Design Optimization

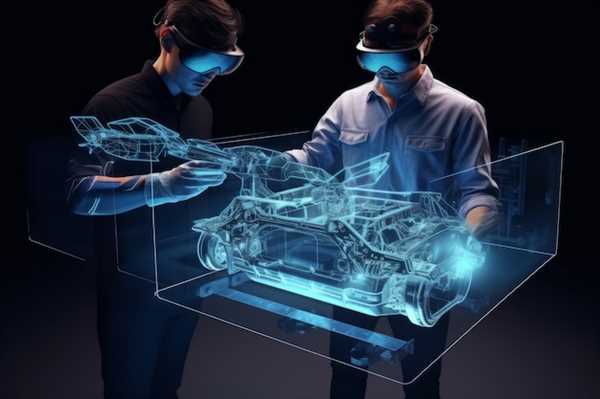

Leverage machine learning algorithms to analyze performance data from previous iterations of power units. This approach identifies key design variables that significantly impact performance metrics like torque and fuel efficiency. Implement real-time data streaming from sensors during testing phases to feed models and optimize parameters dynamically.

Utilize predictive analytics to forecast engine behavior under various operational conditions. By simulating environmental variables and load scenarios, engineers can refine geometries for combustion chambers and exhaust systems based on predicted outcomes. This method reduces the need for extensive physical prototyping.

Explore the synergy between computational fluid dynamics (CFD) software and AI for optimizing airflow within manifolds. Advanced data processing can significantly shorten simulation times, allowing for rapid iterations and adaptations based on analysis results. This adaptation accelerates the development cycle and enhances performance outcomes.

Incorporate genetic algorithms for multi-objective optimization challenges, balancing power output and emissions standards effectively. By allowing computer algorithms to mimic evolutionary processes, striking an ideal balance between competing requirements becomes achievable while maintaining compliance with regulations.

Integrate predictive maintenance solutions using AI-driven analytics to assess engine health. By accumulating and interpreting sensor data over time, potential failures can be identified before they manifest, ensuring reliability and reducing costly downtime during critical racing events.

Future Trends: Alternative Fuels and Sustainable Engine Solutions

Invest in the development of biofuels derived from organic matter, which can greatly reduce carbon emissions. Engage in research partnerships with companies focused on synthetic fuels that mimic traditional petrol but are more environmentally friendly.

Integrate hybrid systems combining electric power and combustion propulsion. This approach maximizes performance during races while mitigating environmental impact. Consider utilizing hydrogen fuel cells as a clean energy source with fast refueling capabilities.

Implement advanced materials in construction that enhance durability and efficiency. Carbon composites can significantly lower weight without compromising strength, allowing for improved energy consumption during races.

Adapt to AI-driven management systems that optimize performance based on real-time data analytics. This will not only refine fuel consumption but also enhance overall operational efficiency.

Explore the use of recycled materials in building components, promoting a circular economy within the automotive sector. This reduces waste and encourages sustainable practices throughout the manufacturing process.